3D vehicle scanning is a revolutionary technology offering precise digital models of cars, trucks, and classics, transforming auto repair and maintenance. By combining LiDAR, photogrammetry, and high-resolution imaging, it facilitates accurate damage assessment, enhanced repair planning, and superior quality control, streamlining workflows and reducing costs. This game-changing process benefits technicians and customers alike with faster, more efficient service, ensuring visually appealing and structurally sound repairs.

“Unleashing the Potential of 3D Vehicle Scanning: A Comprehensive Guide for Technicians

The modern automotive industry is revolutionizing its processes with 3D vehicle scanning, a game-changer in precision engineering. This technology captures detailed 3D models of vehicles, offering immense benefits from design to repair. This article provides an in-depth look at the basics, practical applications, and future trends of 3D scanning, equipping technicians with key insights to enhance their work. Discover how this innovative process optimizes efficiency, precision, and cost-effectiveness across various automotive sectors.”

- Understanding the Basics of 3D Vehicle Scanning

- – Definition and importance in modern automotive industry

- – Key technologies used in 3D scanning of vehicles

Understanding the Basics of 3D Vehicle Scanning

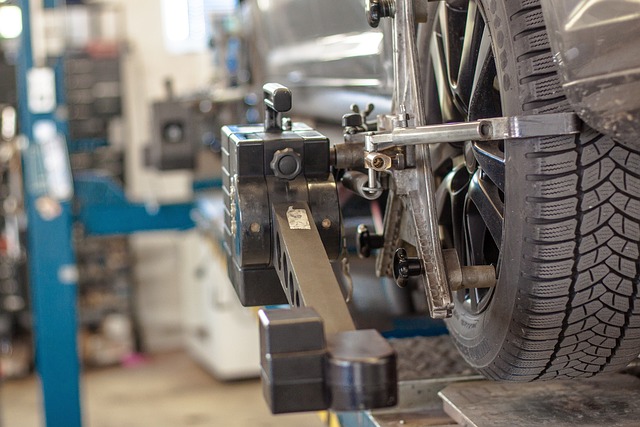

3D vehicle scanning is a revolutionary technology that offers an accurate digital representation of vehicles, providing invaluable insights for technicians across various industries. This process involves capturing millions of data points using advanced sensors to create detailed 3D models, allowing for precise measurements and analysis. By understanding the fundamentals of this technology, auto body repair technicians can leverage its capabilities to streamline their workflow, from assessing damage in tire services to identifying intricate details during dent removal and auto dent repair processes.

The benefits are vast; it enables technicians to visualize vehicle structures in a three-dimensional space, facilitating more effective damage assessment and repair planning. With 3D scanning, every angle and dimension can be captured, ensuring repairs are not just visually appealing but also structurally sound. This advanced method of inspection helps detect even the subtlest imperfections, enhancing overall quality control in tire services and dent repair processes.

– Definition and importance in modern automotive industry

In today’s digital era, 3D vehicle scanning has emerged as a game-changer in the modern automotive industry. This advanced technology involves capturing detailed, three-dimensional models of vehicles, providing technicians with an unprecedented level of accuracy and insight. By using specialized equipment to create precise digital twins of cars, trucks, and even classic vehicles, 3D scanning offers a multitude of benefits for auto repair, maintenance, and customization.

For technicians engaged in tasks such as auto frame repair, auto glass replacement, or intricate auto painting jobs, 3D vehicle scanning is an invaluable tool. It ensures precise measurements and accurate restoration, allowing for more efficient and effective work. With 3D models, technicians can virtually inspect and assess damage, plan repairs, and predict outcomes before ever touching the actual vehicle. This not only enhances the quality of repairs but also streamlines workflows, making auto service and customization processes faster, more cost-effective, and ultimately, better for both technicians and customers.

– Key technologies used in 3D scanning of vehicles

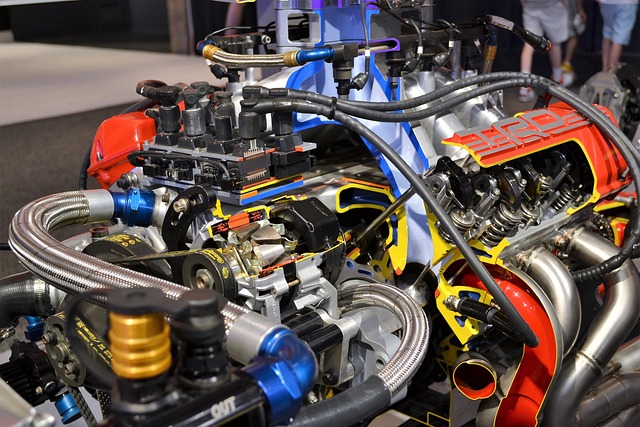

The core technologies powering modern 3D vehicle scanning involve a combination of LiDAR (Light Detection and Ranging), photogrammetry, and high-resolution imaging systems. These advanced tools enable technicians to capture detailed, accurate digital representations of vehicles, including their exterior shapes, interior layouts, and even subtle surface imperfections.

LiDAR sensors project light pulses onto objects and measure the time it takes for them to reflect back, providing precise distance data that creates a 3D point cloud. Photogrammetry utilizes multiple high-resolution images taken from different angles to construct 3D models through image stitching and reconstruction. Together, these technologies facilitate comprehensive inspections, aiding in tasks such as car dent repair, frame straightening, and vehicle paint repair by offering an unparalleled level of detail and accuracy.

3D vehicle scanning is transforming the automotive industry by offering accurate, detailed digital representations of vehicles. By understanding the basics and key technologies behind this process, technicians can leverage its potential for improved precision, efficiency, and quality control in their work. As 3D scanning continues to evolve, embracing these insights will be crucial for staying ahead in the modern automotive landscape.