3D vehicle scanning revolutionizes auto repair and restoration with non-invasive digital imaging, creating accurate 3D models for detailed inspections. This technology enables precise measurements, especially beneficial for dent repair, ensuring aesthetic and structural integrity. By streamlining work processes and enhancing quality, 3D scanning is a game-changer, reducing human error, saving time, and improving customer satisfaction.

“Revolutionize your auto repair process with the cutting-edge technology of 3D vehicle scanning. This advanced technique offers an unprecedented level of precision and efficiency in diagnosing and repairing vehicles. In this comprehensive guide, we explore the benefits of integrating 3D scanning into your shop, from enhancing accuracy to streamlining workflow. Learn how this technology can become a game-changer for your business, ensuring top-tier repairs and customer satisfaction. Discover the step-by-step approach to effectively integrate 3D vehicle scanning today.”

- Understanding 3D Vehicle Scanning Technology

- Benefits of Implementation in Auto Repair Shops

- Step-by-Step Guide to Effective Integration

Understanding 3D Vehicle Scanning Technology

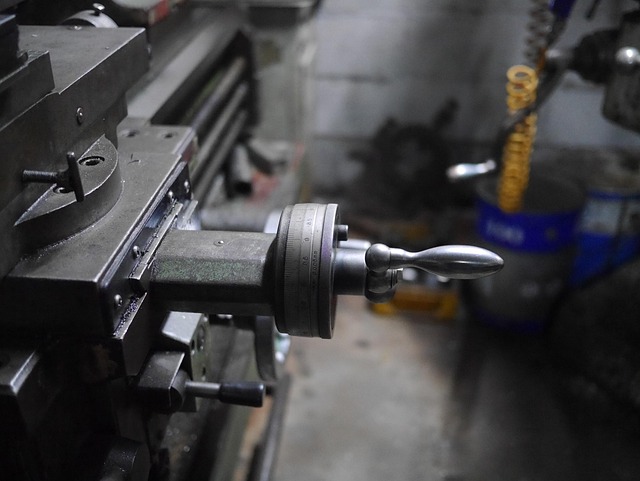

3D vehicle scanning technology has revolutionized auto repair and restoration processes. This innovative approach involves capturing detailed digital images of vehicles from multiple angles to create an accurate 3D model, offering a non-invasive method to inspect and assess both exterior and interior components. Unlike traditional measurement techniques, it provides a comprehensive view of the car’s geometry, enabling technicians to identify even subtle imperfections or damage.

The process is particularly beneficial for intricate tasks such as dent repair and automotive body work, where precision is key. By digitizing the vehicle’s surface, 3D scanning allows for exact measurements, ensuring that repairs are not only visually appealing but also structurally sound. This advanced technology is a game-changer in the industry, streamlining work efficiency and enhancing the overall quality of car restoration efforts.

Benefits of Implementation in Auto Repair Shops

The implementation of 3D vehicle scanning in auto repair shops brings a multitude of benefits that significantly enhance efficiency and quality. By capturing precise digital representations of vehicles, mechanics gain access to detailed models that offer a clear view of every component, from exterior paneling to intricate engine parts. This technology revolutionizes how repairs are conducted, especially in complex cases like dent repair or vehicle restoration. With 3D scanning, auto body repairs become more accurate and consistent, ensuring that each replacement part is tailored precisely to the vehicle’s unique specifications.

Moreover, 3D vehicle scanning streamlines the entire process, from initial damage assessment to final quality control. It reduces the reliance on traditional measuring methods, which can be time-consuming and prone to human error. With this advanced technology, mechanics can quickly identify issues, plan repairs, and even predict potential future problems. This not only saves time but also contributes to improved customer satisfaction by delivering superior vehicle aesthetics and performance after auto body repairs or dent repair treatments.

Step-by-Step Guide to Effective Integration

Applying 3D vehicle scanning in auto repair offers a game-changing precision for collision repair services and automotive repair services. Here’s a step-by-step guide to effective integration:

1. Invest in 3D Scanning Technology: The first step is acquiring a high-quality 3D scanner suitable for your workshop’s needs. These scanners capture detailed, precise data of vehicle surfaces, including complex geometry and paint imperfections. Consider factors like scanning speed, accuracy, and the types of vehicles you’ll be working on when making your selection.

2. Prepare Your Workspace: Designate a dedicated area for 3D scanning, ensuring it’s free from obstructions and has adequate lighting. Calibrate your scanner according to manufacturer instructions to ensure accurate measurements. Position the vehicle correctly on the scanning platform, securing it safely to prevent movement during the scan process.

3. Scan the Vehicle: Initiate the 3D scanning process, carefully following the scanner’s guidance. Ensure complete coverage of the vehicle’s exterior, including all panels and surfaces that may require collision repair services or vehicle paint repair down the line. The resulting 3D model will serve as a precise digital blueprint for your work.

4. Analyze Data and Plan Repairs: Utilize specialized software to visualize and analyze the 3D scan data. Identify any damage, deformities, or paint imperfections, which can aid in planning comprehensive automotive repair services. Compare the digital model with pre-existing standards or manufacturer specifications to ensure accurate repairs.

5. Execute Repairs with Confidence: With the detailed insights from the 3D scan, proceed with confidence when performing collision repair services or vehicle paint repair. The precise data ensures minimal wastage of materials and helps achieve a seamless finish, enhancing customer satisfaction with your automotive repair services.

3D vehicle scanning is not just a futuristic concept but a powerful tool for modern auto repair shops. By integrating this technology, businesses can enhance precision, streamline diagnostic processes, and ultimately improve customer satisfaction. The benefits outlined in this article highlight how 3D scanning can revolutionize auto repair, making it an essential investment for any shop looking to stay competitive and efficient in today’s market. With the right implementation strategy, as outlined in our step-by-step guide, auto repair professionals can unlock a new level of excellence.